Closed-Loop Microstepping

SPM mode is intended for applications where the only concern is end point accuracy. When it is necessary to continuously correct for error, Galil offers Closed Loop Microstepping (CLS) mode. Figure 6 shows the stepper system now being driven in CLS mode. In addition to the reference position and encoder position, an error signal (green line) is now generated internally on the controller and is used to adjust the stepper motor's position continuously. It is important to note that in CLS mode motion is now profiled based on the encoder position, but step pulses are still generated by the controller to drive the stepper motor.

The error signal generated is fed through Galil's CLS filter which then compensates for any error present in the system by adjusting the step pulses output to the stepper. Closed Loop Microstepping is a true closed loop mode of operation, and is the optimum use of a stepper motor still being driven as a stepper. Closed loop operation brings with it the risk of instability if the loop is not correctly tuned, so care must be taken to achieve stability. Furthermore, this mode is still power inefficient and has low bandwidth when compared against a classic servo system. This low bandwidth can be made even lower when using external 3rd party stepper drives with low current loop bandwidth and non-linear characteristics.

Driving a Stepper as a 2-Phase Brushless Motor

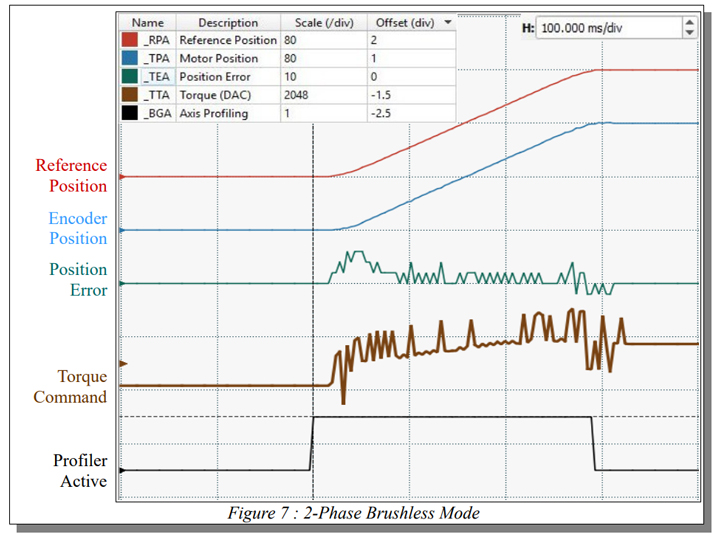

To achieve the highest performance, the stepper motor can be treated as a 2 phase brushless servo motor. Current to the motor will then be controlled as a function of the error signal just as with standard servo motors. Galil refers to as 2 Phase Brushless mode, or 2PB. Figure 7 details the stepper motor system being driven in this mode. Now, rather than step pulses, a torque command signal (brown line) is generated by the controller to be fed to one of Galil's internal amplifiers operating in 2PB mode in order to control the position of the motor. times. A stepper motor driven in 2PB mode is analogous to a classic servo motor attached to a speed reduction gearbox. Because this mode operates like a standard servo motor, the full range of Galil's advanced PID filter capabilities can be now utilized, including the notch, pole, and feedforward filters. In order to drive the stepper motor in this way, the amplifier must be made more sophisticated to properly deliver only the instantaneous required current to the motor. This results in the stepper motor running power efficiently and causes it to generate far less heat.

Closed Loop Stepper Control

By leveraging Galil's methods of closed loop stepper control, the various shortcomings of stepper motors can be overcome. The endpoint position can be adjusted for inaccuracies with stepper position maintenance mode, the position can be dynamically adjusted with closed loop microstepping, and lastly the stepper motor can be treated as a 2-phase brushless servo to further increase the performance and efficiency of the motor.

https://blog.she.com/dkjfjk/2015/09/25/nema-motor-frame-sizes-and-what-they-mean/

http://blog.she.com/dkjfjk/2015/10/18/which-is-difference-bettween-4-wire-6-wire-and-8-wire-stepper-motor/